Finishing and printing

In order to subsequently give the well-formed injection-molded parts their unmistakable appearance, a wide variety of finishing processes are available. With tried and tested processes such as electroplating, very sophisticated design elements can be created that give your products that special touch.

Process for finishing

We would be happy to show you the possibilities to optimize your products with a perfect finish. Choose between chrome-plating, gold-plating, painting or printing of components - we will be happy to provide you with information to determine the most suitable process for plastic refinement.

Painting

Design as well as functional surfaces are coated with specially coordinated paint systems according to customer requirements. The paintwork is used from design specifications or as a functional part. Functional surfaces such as "soft touch" or EMC protection (electromagnetic shielding) can give the part the functionality it needs in its application. Coatings can also be used as scratch or weather protection.

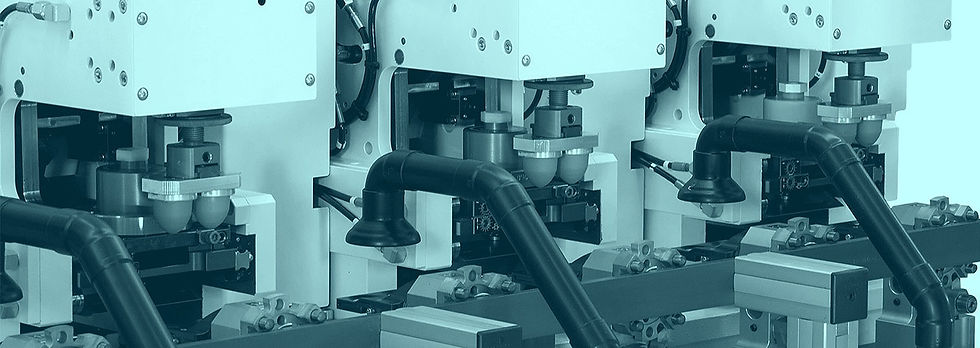

Electroplating

Electroplating creates parts with a metallic surface. These surfaces can be made shiny or matt like chrome, for example. However, other metallic surfaces such as nickel or gold are also possible.

Printing

The printing offers you a variety of design options - from simple single-color printing to multi-colored printing. We use pad printing, screen printing and hot stamping for labeling / printing.

Consider the following: regardless of whether it is a high-quality furniture part or an injection-molded part - it is only the combination of a functional design, high-quality materials, precisely manufactured parts from production, paired with an appealing finish that ultimately makes the difference - that is what we mean by quality.

When all these properties are met, one can speak of a perfect product.